Philosophy

Every business needs a set of philosophies to live by and share. Here are ours:

Design

Our design philosophy lies at the core of building safe, innovative, functional, and reliable vessels, as well as overland vehicles and performance apparel. Great design is more than just good aesthetics; it is the way we use a product. Only then do you experience all the subtle touches; the ingenious visible and invisible aspects that make a great design exceptional.

Creating our products a hugely complex task involving a myriad of people, processes, and systems that are all required to work efficiently together for years at a time. To make an exceptional vessel, vehicle, or wearable is a challenging task, and one that without a set of core design beliefs would be almost impossible to achieve. The following details the kind of questions we ask ourselves throughout the design process.

Product

At Arksen we are building explorer vessels, vehicles and apparel with purpose. We seek to inspire others that the ‘oceanic poles of inaccessibility’ are accessible for all and instil in people the importance of exploring earth to greater understand our impact on them. By ensuring that our products can perform safely, reliably and predictably, even in the harshest conditions in the wildest and remote parts of the world, we hope to change the individual’s view of what is possible.

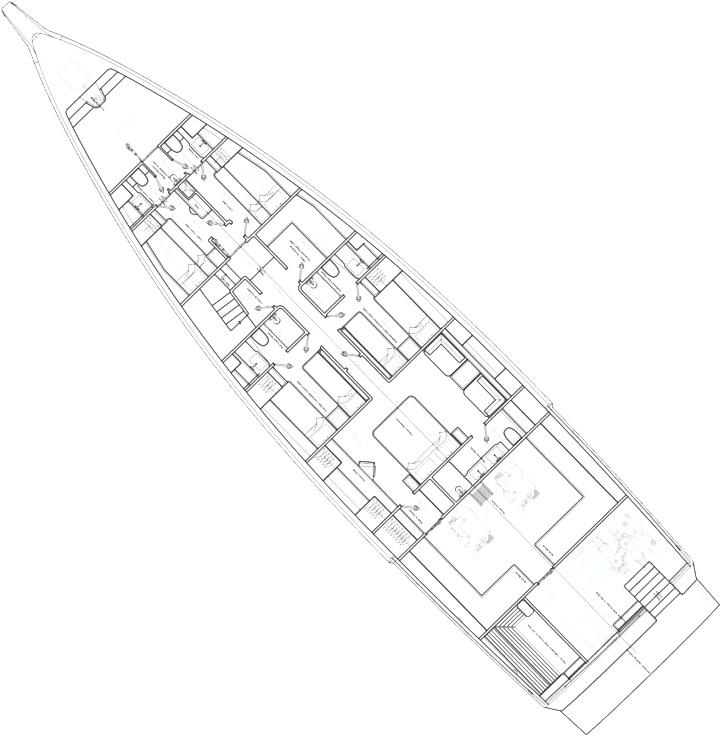

The Arksen 85, for example, has unique capabilities; ice-strengthened structure and exceptional sea keeping. In a calm sea at 7knts the power requirement is just 12kw. It offers 7000 miles of cruising on a single tank of fuel and at just1.55m draft it can visit the shallowest bays and rivers. Industrial grade systems engineered for minimum maintenance aredesigned to make the most demanding adventures possible.

Our apparel and our overland vehicles are designed with the same uncompromising approach – combining functionality and design integrity to deliver outstanding performance.

Partnership

We find companies and individuals that we like, and we form long term partnerships that allow us to problem solve, invent, build and support our products together over their lifetime.

In building the Arksen business we have sought to partner with like-minded companies which share our vision for a sustainable marine future using pioneering technologies that we believe will transform the marine industry over the next decade.At the core of this approach lies our relationship with our owners and our commitment to them to provide extemporary customer services and striving to make their lives as simple as possible. This starts with the online systems for technical documentation and FAQs through to providing hands on and in person support. Utilising our established global network of service providers , we can support our products no matter where they are in the world.

Manufacturing

There is no getting away from the fact that we manufacture goods and that in doing so we use earths precious natural resources. Our approach to manufacturing is based on minimising use of damaging or environmentally sensitive materials and seeking out the sustainable options. And to work with manufacturing partners who are equally committed to environmental sustainability.

Sustainability

Sustainability is a core focus at Arksen, and as such we have to ensure that any action taken is viewed through this lens. We understand that this not only relates to the design and building of our products but also internally and throughout our chosen partnerships. Therefore, a clear set of sustainable working practices are distributed and understood across the company in order to remain transparent. Sustainability is not just a messaging pillar we use as a marketing tool, it is a core belief and although we understand our own limitations, we must take steps in the right direction.

This is a significant task in a large vessel because of the vast array of components and suppliers. Our approach is to partner with manufacturing and engineering companies that themselves have holistic environmental and recycling policies and to work with them to ensure the integration of all the components does not unduly hinder end of life recycling. Beyond that our choice of construction and fit out materials starts from the premise that they must be sustainable at source and easily recyclable at the end of life.

We believe in and continuously work towards a number of the 2030 Agenda for Sustainable Development, which was adopted by all United Nations Member States in 2015, provides a shared blueprint for peace and prosperity for people and the planet, now and into the future. At Arksen we understand that contributing to achieving the SDGs is not only a responsibility but also a business opportunity and we will deploy the goals to shape our own internal targets and integrate sustainability into our core business strategies.

We are also working hard through Arksen Philanthropy to partner with existing and upcoming organisations who are committed to adding to the knowledge of and reducing the adverse impacts on our environment.