What makes the best waterproof jacket?

When it comes to protection from the elements, there is no one-size-fits-all. A jacket that performs perfectly on the high seas will not be the same one you want to rely on when you’re on a mountain trail ; likewise, the pack-away waterproof you grab every day is not quite what you need when you’re carving down powder slopes .

A waterproof jacket is the outermost layer, designed to work with what goes beneath – but as the final connection to the outer elements, it is one of the most important garments of all, working both as a shield from rain as well as a regulator for heat.

Performance gear manufacturers like Arksen are constantly innovating to advance the quality and performance of outdoor apparel and the selection of new materials, attention to detail and alternative design approaches are all fundamental in that development process.

The developments can create improvements across the board – bringing global advantages in waterproofing, breathability, durability, packability, fit and comfort – but leading brands tend employ them to develop products with qualities that are tailored for particular needs.

An increasing ‘situation specification’ approach is leading to greater differentiation between garments suited to different use cases – and Arksen has developed a range of four key waterproof jackets, each of which is specifically focused on a specific role.

The company’s rainwear range combines marine-grade toughness with alpine precision, using world-class fabrics and design details proven in the harshest conditions – and at the forefront of each one there are three key elements: fabric, cut and detail.

Fabric

Fabric is the foundation of a waterproof jacket, core to dictating its protection against the elements while also keeping the occupant comfortable. Early materials relied on heavy waxed cotton or rubber, which while effective against rain were stiff, bulky and poorly ventilated, but over time, advances like Gore-Tex have revolutionised rainwear.

These lightweight, breathable membranes repel water while allowing perspiration to escape – and today, modern fabrics often combine multiple layers, with outer shells and inner membranes coupled with durable water-repellent (DWR) coatings.

Arksen’s Foul Weather Jacket uses a three-layer marine-grade polyurethane laminate which offers 20,000mm waterproofing and 20,000g breathability, with a heavy-duty oxford nylon face that enables it to resist relentless spray and heavy downpours.

The Idun jacket, meanwhile, is built on a Schoeller® three-layer material, which is durable, weatherproof and breathable, and the Obex uses a c_change™ adaptive 3-layer membrane that offers +10,000mm waterproofing and a 9,000 Moisture Vapor Transmission Rate.

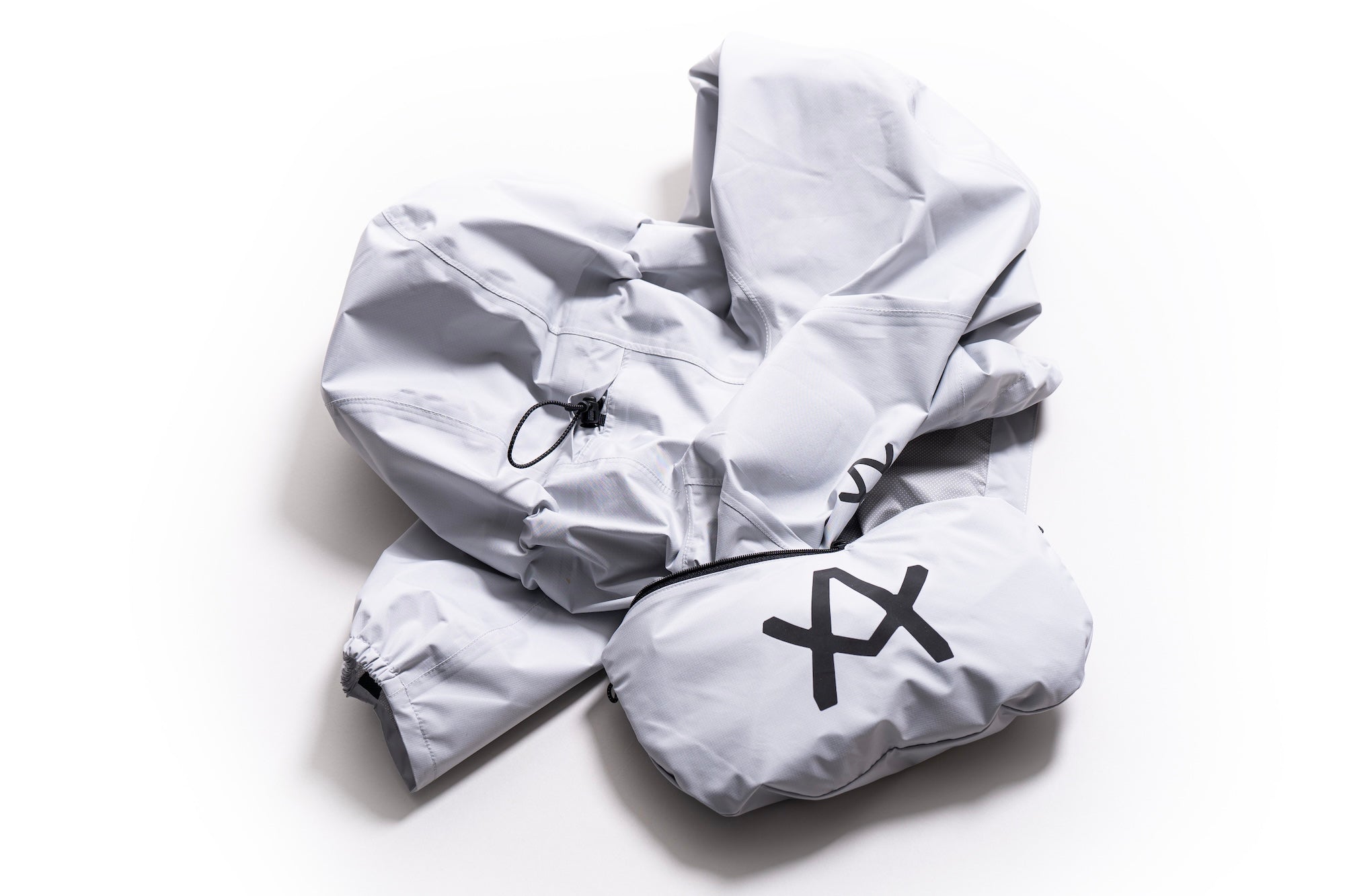

Both of these offer an ideal base to couple with different design details for different use cases, while the lightest garment in the range, the Cayus, uses the ultralight and waterproof Pertex® Shield 2.5-layer material to deliver ultimate packability.

Cut

The cut of a waterproof jacket determines not only its comfort but also its functionality in real-world conditions. Just as cars have become more complex thanks to improved manufacturing, modern clothing has moved from sometimes boxy and oversized designs to tailored, ergonomic cuts that accommodate movement and layering.

Garments can now be literally tailored for specific activities — articulated sleeves for climbers, high neck hoods for sailors – while design and engineering can also reduce excess bulk, improving packability and comfort while allowing for adjustable elements that can offer exceptional customisation and enhance protection.

This evolution in cut represents a shift from simple rain protection to performance gear designed around human movement, and advances in 3D, body-mapped design now allow far more complex creations.

Arksen’s Foul Weather Jacket, for example, offers ultimate weather resistance but its extended drop tail and articulated sleeves provide unhindered movement, while the Idun is more balanced to offer protection without bulk, enabling high versatility in any setting.

The Obex jacket is tailored for the mountains, with an alpine profile that offers an optional powder skirt and a trim fit, while the slim, athletic fit of the Cayus is designed to be layered, optimising its use for fastpacking, trail running, ultralight trekking and travel.

Design detail

This is the area of development where innovation can have a huge effect in the usability of a garment, transforming a waterproof jacket from basic protection into a personal support system.

Traditional raincoats lacked refinement, but modern jackets include an unprecedented depth of detail, with multiple adjustment points, water-resistant zips, storm flaps, pit zips, adjustable, laminated seams, chin guards and drawcord hems to name a few innovations.

These are all made possible by improvements in construction precision, thanks to techniques such as laser cutting and bonding, allowing modern designs to incorporate complex gadget-style features with lightweight, low-bulk solutions.

Arksen’s Foul Weather Jacket, for example, has a strong reinforced hood brim and carefully positioned drainage channels to filter away the rain. It also has corrosion-resistant zips to provide long-term resilience to relentless conditions out on the ocean.

The Idun Jacket is streamlined but has an adjustable storm hood to suit different situations; the Obex has a helmet-compatible hood and reinforced shoulders for pack straps; and the Cayus has a minimal seam design that allows it to be stowed in its own pocket.

All these innovations are not achieved by chance. Thousands of hours of research and development goes into the creation of such precision-engineered apparel – and when it’s out in the field, those situation-specific solutions really prove their worth.