Arksen 85 Insight: The tech beneath the waves

In the first of a series of blogs delving into the design and engineering of the Arksen 85 , we dip beneath the waterline to discover the technology that delivers its class-leading stability, range and efficiency.

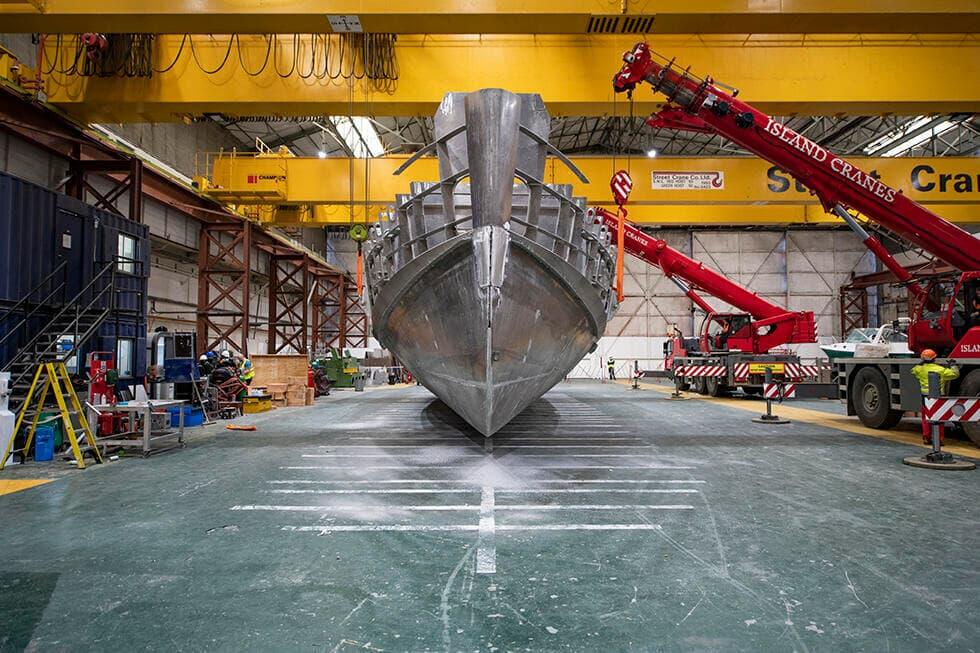

The stunning aluminium-built Arksen 85 Explorer Yacht is engineered to perform in all conditions, whether it’s cutting through waves on long-distance ocean voyages or bobbing on gently a rolling sea while sat at anchor.

The innovative and well-proven Modeshift® Hullform, developed by Humphreys Yacht Design, provides the baseline for the vessel’s class-leading efficiency and stability, but it is the combination of a number of technologically advanced and hydrodynamically developed features beneath the water that hone it to perfection.

BUILT-IN HULL EFFICIENCY

The chine, at the bow, and the propellor tunnels, at the stern, are two design features that play an integral part of the hull design but which take its performance to another level – one in the area of comfort, the other in efficiency.

Jim Mair, Arksen’s Chief Technical Officer, Marine, explains: “The chines are really effective at deflecting spray and when it is combined with the high freeboard and the enclosed bulwarks, it creates a really dry space on deck, so they are a really important feature.

“Then, down at the stern, the propellor tunnels provide a really smooth flow of water over the prop but also enable us to really pull the props up into the hull, reducing the draft – so although we’ve got a one metre diameter prop, our draft is only one and a half metres.”

The underside of the vessel has a non-ablative anti-fowling coating used to keep the hull clean. This enables it to maintain better efficiency through the water and also reduces maintenance requirements, without release biocides into the water as some coatings do. Any fouling that starts to accumulate, when the vessel is at rest, just washes away as the boat starts to move through the water.

To further maximise the lifetime of the vessel, without impacting hull efficiency, a number of zinc sacrificial anodes have been recessed into the hull, to protect the underwater materials from galvanic corrosion, without adding contributing to drag.

ACTIVE FINS

The Arksen 85 has three different options of stabilisation, one of which is provided by two active fins on the side of the boat. One of its most interesting features, they can rotate up to 180 degrees to maximise roll reduction when both underway or at rest.

Mair explains: “As with most normal fins, they’re designed and sized to be really effective underway but when you enter anchoring mode, they flip 180 degrees and are able to provide another really effective solution when the boat is stationary.

“A conventional fin will actually walk you towards your anchor slightly and lose that tension in the anchor cable, making the bow wander a little bit. However, when these fins flip, they walk you aft, so they actually put tension on that chain cable.

“This feature doubles down on their capability to create additional comfort because you're rolling less – as you're head to the conditions – and you've also got the effect of them actuating. They are a really nice piece of kit.”

INTERCEPTORS AND THRUSTORS

Another active element beneath the waves is the interceptor system, in which a number of active blades are set out across the stern. This is uncommon on slower boats, but they were introduced on the Arksen 85 after tank testing indicated major benefits for stability.

“Above speeds of around about 10 knots, the deployment of the blades on these interceptors is really effective at controlling the pitch of the boat,” says Mair. “That brings your stern up, reduces your transom immersion and reduces your resistance.

“They also work in an active mode with the fin stabilisers to provide a form of active ride control – so if you're turning or the boat is just rolling slightly, the hydrodynamic effect of those interceptors being deployed makes a real contribution to the comfort.”

The propulsion system brings with it another highly effective active tool, with a 50hp bow tunnel thruster and a 50hp swing-down stern thruster working in tandem to provide exceptional station-holding capabilities.

“At the press of a button, the boat will use these to stay in its own position,” adds Mair. “It works really effectively as a virtual anchor if you’re in a sensitive area and are not able to drop anchor or if you want to hold position for a short time in deep water.”

SKEGS AND RUDDERS

Towards the rear, the prominent pair of skegs are first and foremost designed to protect the propellers and rudders. However, unlike on most boats, these have an added functionality, working in combination with the keel to enable full grounding of the boat.

Right from the early stages of the design process, the Arksen 85 was designed to deliver ultimate explorer vessel capabilities. One of the functionalities the team identified to achieve was for it to be able to safely ground in remote locations.

As a result, significant focus was placed on the structural integrity of the skegs during the engineering phase and Mair explains: “They’re heavily engineered to take to the ground either on a drying grid or, for the more adventurous, out in a tidal waterway.”

Directly behind these skegs and the propellors that they house sits another innovative solution – a pair of CJR-developed flow-aligned rudders that only do their job exceptionally well but are also a visually stunning piece of engineering.

Designed through the use of Computational Fluid Dynamics (CFD), the rudders have been precision engineered for performance, resulting in a shapely form that is completely different to conventional straight design.

“The rotational nature of the wash coming off the propeller, and the way it interacts with the rudder in different places, means that a conventional flat rudder will have some areas where it's interacting nicely and others where it's creating drag, noise and vibration.

“These rudders have been paired to match the propellers, so the twisted profile is optimised to match the wash coming off the propeller. Wherever that wash hits it, there is a much, much higher level of optimisation of that flow and that reduces noise and vibration.”

Ultimately, all these innovations combine with the complex hull design to provide improved efficiency, reduced fuel consumption and class-leading levels of stability and seakeeping – and much of it is thanks to the hidden engineering sat beneath the waterline.